In the context of the rapid development of today's automobile manufacturing and industrial equipment, the strength, precision, and consistency of chassis structural parts have become more important than ever before. Behind this, it is the die-casting mold that plays a key role. Especially in the production of chassis structural parts, a set of high-quality die-casting molds not only directly affects the performance of the parts but also the safety and service life of the whole vehicle or equipment. So, why are die-casting molds so critical? This article will show you multiple dimensions.

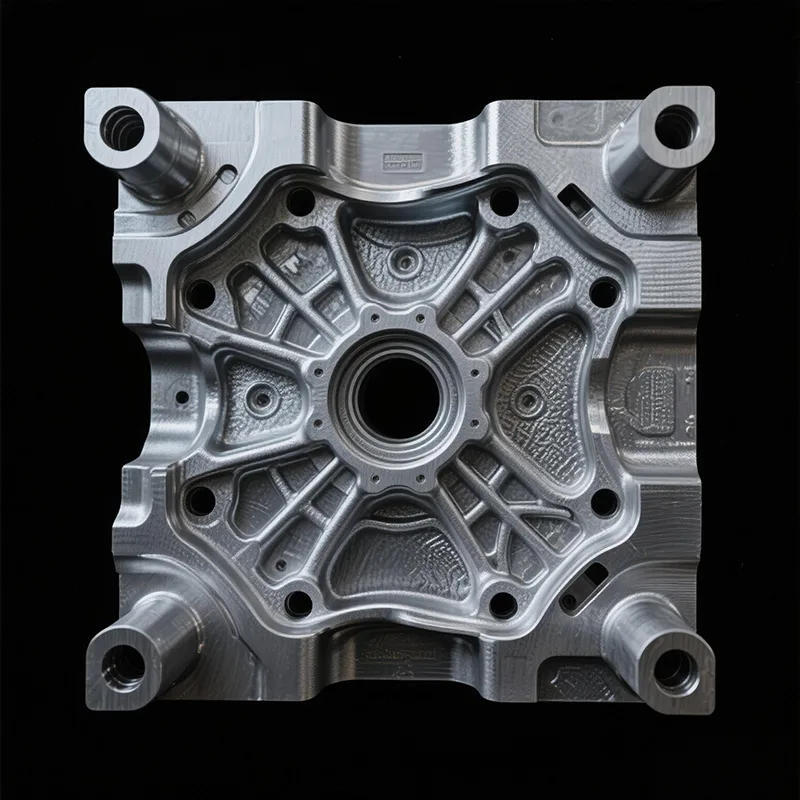

The structural parts used for the chassis often need to withstand extremely high impact and loads, such as suspension brackets, subframes, connecting rods and other parts. Only by using high-precision, high-pressure resistant Die Casting Molds for Chassis Structural Components can dense, pore-free metal filling be achieved in the die-casting process of aluminum alloys or magnesium alloys, thereby casting high-strength, high-stability structural parts. In particular, the mold design using vacuum die-casting or semi-solid die-casting technology can significantly improve the mechanical properties of parts, which is an indispensable production method to cope with the trend of lightweight automobiles.

Most chassis structural parts are mass-produced, and the dimensional consistency is extremely high, otherwise it is easy to cause assembly errors or structural eccentricity. Our factory's Die Casting Molds for Chassis Structural Components can effectively ensure that the wall thickness of each casting is consistent, the shrinkage is balanced, and the precision error is controlled within the micron level through precision CNC machining, simulated flow analysis and thermal field optimization design.

For overseas buyers, this means a lower rework rate and a higher delivery qualification rate, and also saves a lot of production and assembly costs.

Hyundai Die Casting Molds for Chassis Structural Components not only pursues mold cavity accuracy, but also continuously optimizes mold life, cooling system, demolding structure, etc. By using high-strength alloy steel materials and heat treatment technology, the mold can withstand tens of thousands of high-pressure injections without deformation, greatly extending the mold life and reducing the frequency of mold replacement. Coupled with the design of automated demoulding and rapid cooling systems, the entire die-casting production line is more efficient, suitable for mass production needs, and saves buyers a lot of manpower and time costs.

As the automotive industry transforms towards lightweight and electrification, chassis structures are no longer dominated by traditional steel parts. The combination of die-casting molds and aluminum/magnesium alloy materials makes complex hollow structures and one-piece molded parts possible. This structural integration design not only reduces the weight of the vehicle, but also improves the overall torsion and fatigue resistance. From a design perspective, die-casting molds for chassis structural components can be customized through CAE analysis, supporting structural optimization, integrated functional components, and even embedded parts die-casting and other advanced processes.

Although the automotive chassis is one of the main application areas of die-casting molds, this technology is also applicable to heavy machinery, engineering equipment, rail transit, electric two-wheeled vehicle chassis structure, electronic control system housing and other scenarios. Die-casting molds provide an ideal solution for any industry that has high requirements for structural strength, dimensional accuracy and production efficiency.

Yuyao Huantong Metal Products Co., Ltd. is mainly engaged in the manufacturing and processing of hardware accessories for machinery, construction, and electrical industries. We provide customers with high - value - added customized products. Learn more about what we offer by visiting our website at https://www.nbhtmetal.com/. For questions or support, contact us at sale@nbhtmetal.com.

Copyright © 2025 Yuyao Huantong Metal Products Co., Ltd. All Rights Reserved. Links Sitemap RSS XML Privacy Policy