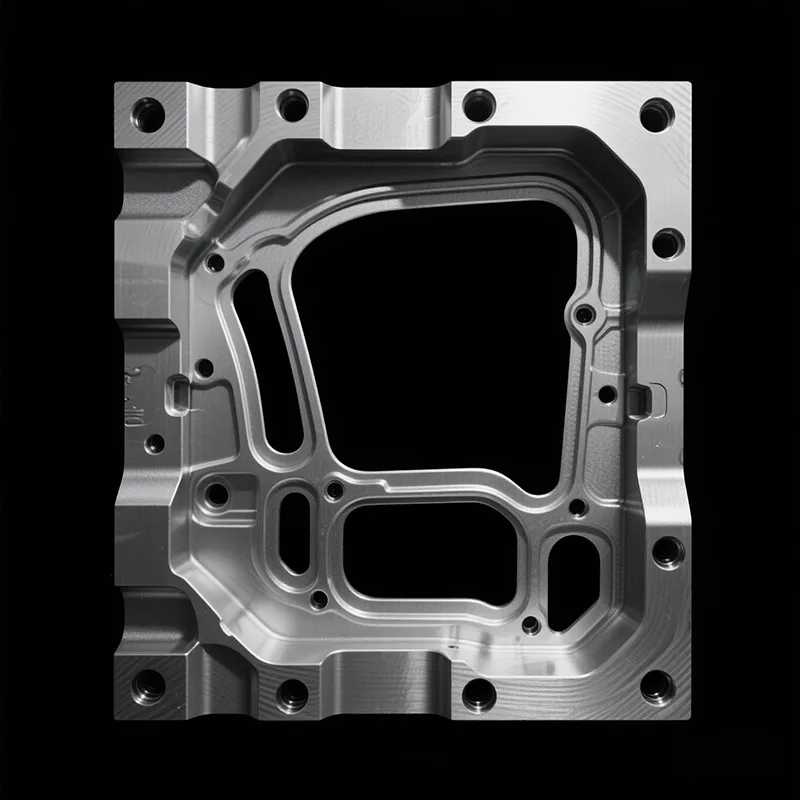

In vehicle manufacturing, body connectors such as door hinges, brackets, and crossbeam connectors are basic components that cannot be ignored. Our die casting molds for vehicle body connectors, which are specially designed for these common structural parts, are becoming ideal production tools for small and medium-sized automotive parts manufacturers with their reasonable design, durable materials, and fast delivery advantages.

Unlike traditional molds that are complex and difficult to debug, our Die Casting Molds for Vehicle Body Connectors have a simple and clear design structure, are practical and efficient, easy to install and debug, and can be quickly adapted to various die-casting sites. It is especially suitable for small or medium-sized manufacturing companies with limited production line resources. It can be quickly put into mass production without large-scale transformation, greatly shortening the project startup cycle.

The mold body is made of high-strength alloy steel and strengthened by professional heat treatment process, with excellent wear resistance and fatigue resistance. The mold life can be stably reached more than 50,000 times, helping customers significantly reduce the frequency of mold replacement and long-term cost expenditure.

· Stable molding: The mold adopts high-precision parting surface design, the dimensional error of the die casting is controlled within ±0.1mm, and the yield rate is as high as 95%, which greatly reduces the risk of rework.

· Easy to maintain: Modular structure, wear parts can be replaced separately, the maintenance cost is only 60% of the industry average, and the maintenance operation is more efficient.

· High surface finish: The mold cavity is finely polished to reduce burrs and defective products. The casting can directly enter the spraying or assembly link, eliminating additional processing links.

· Support multiple materials: Compatible with aluminum alloy and zinc alloy, meeting the diverse needs of multiple industries such as automobiles, electric vehicles, and construction machinery for body connectors.

From drawing confirmation to trial mold production, the entire process only takes 20 to 30 days, which greatly shortens the delivery cycle and seizes the market opportunity. Die-casting molds for vehicle body connectors are widely compatible with 500T-2000T standard die-casting machines, with clear and transparent factory prices and no hidden fees. They are especially suitable for overseas purchasing customers who are sensitive to delivery time and budget.

Whether it is passenger cars, commercial vehicles, electric vehicles, construction machinery, or special vehicles, as long as it involves structural parts connection, our die casting molds for vehicle body connectors can provide high-precision and high-stability molding solutions. We also support customized structural optimization to provide customers with more competitive mold support.

Choosing a good die-casting mold is not only related to the molding accuracy of the product but also affects the efficiency and cost control of the entire production line. Our die casting molds for vehicle body connectors are serving more and more parts manufacturers from all over the world with the core advantages of "reliable, easy to use, and durable". If you are looking for a mold tool that can make production more efficient, this will be a trustworthy choice.

Yuyao Huantong Metal Products Co., Ltd. is mainly engaged in the manufacturing and processing of hardware accessories for machinery, construction, and electrical industries. We provide customers with high - value - added customized products. Learn more about what we offer by visiting our website at https://www.nbhtmetal.com/. For questions or support, contact us at sale@nbhtmetal.com.

Copyright © 2025 Yuyao Huantong Metal Products Co., Ltd. All Rights Reserved. Links Sitemap RSS XML Privacy Policy